Our Enzyme Indicator technology can be effectively applied in any industry sector where H₂O₂ bio-decontamination is used as it remains one of the most effective methods of neutralising contaminants in cleanroom settings and sterile environments where high levels of sterility are required.

Enzyme Indicators offer significant advantages over traditional methods measuring performance instantly, reducing cost, saving time, improving efficacy.

Every cycle can be validated immediately resulting in faster product release, immediate batch verification.

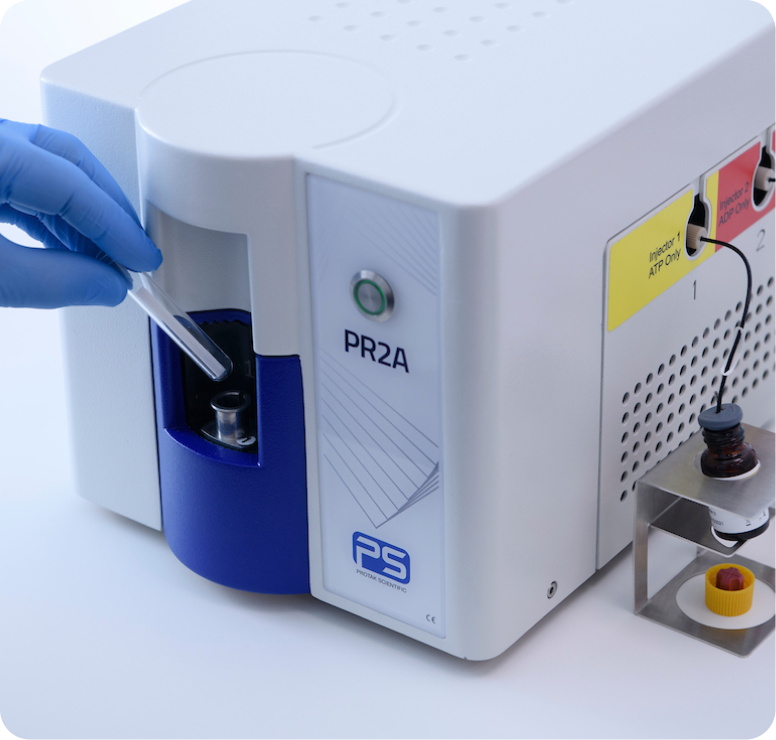

The ATHENA™ software is used alongside Enzyme Indicators to deliver advanced reporting. This user-friendly platform includes enhanced audit and data archive facilities needed during validation cycles.

Read about the advantages and benefits of using our Enzyme Indicators for your H₂O₂ bio-decontamination validation processes.

Biological Indicators vs Enzyme Indicators at a glance.

Presentations, white papers, webinars, shared articles, project summaries and product analysis.